How Edge-Sealed Modules (ESM) Work

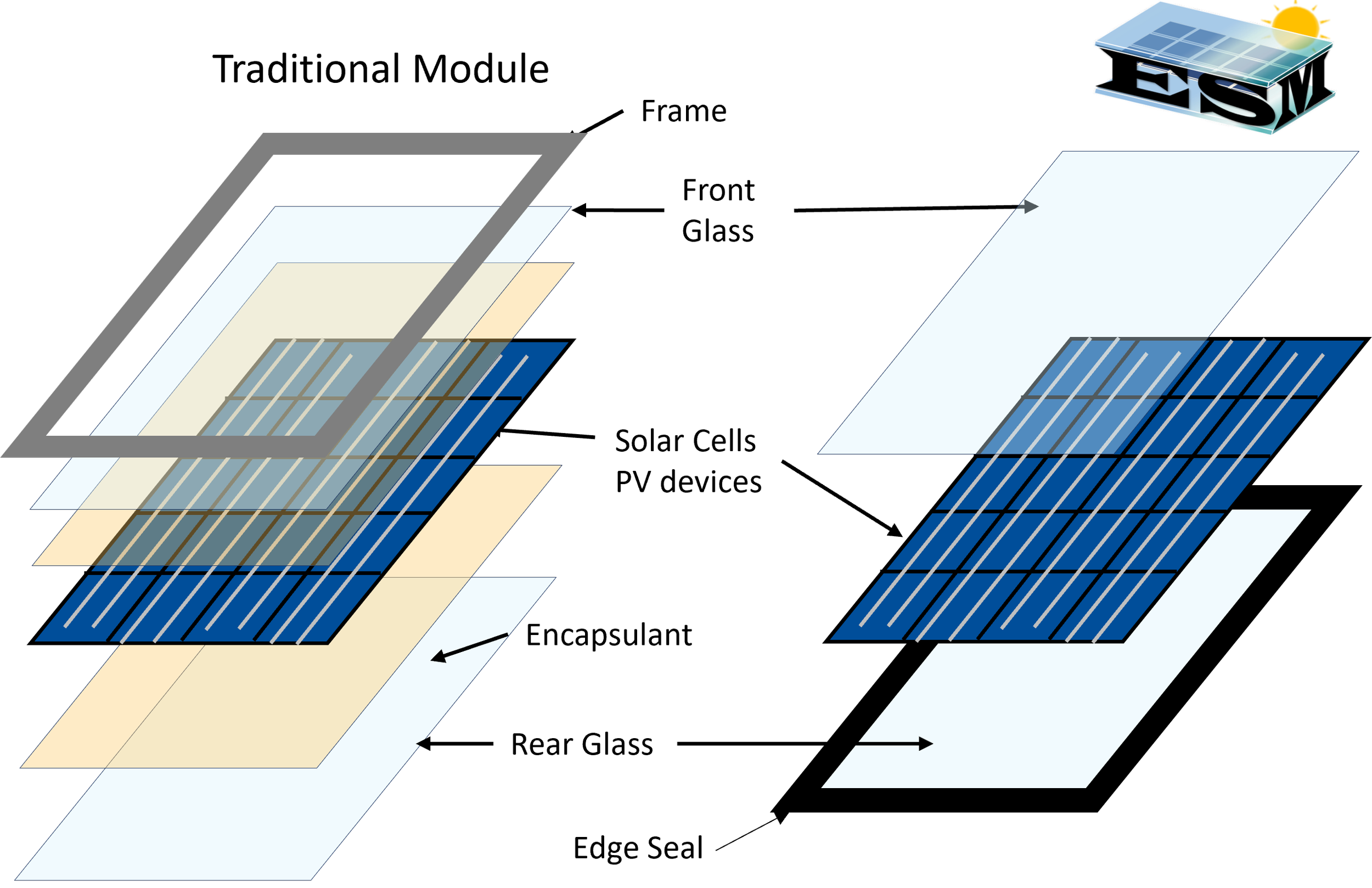

•Eliminates the encapsulant and vacuum lamination process

•Utilizes an edge seal to create a protected internal cavity

•Removes many issues associated with the vacuum lamination process

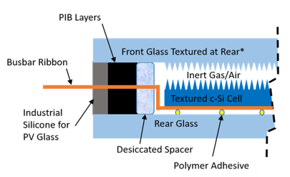

•The air gap formed by removing lamination can lead to losses in optical and thermal performance.

By introducing internal textures, researchers at Colorado State University have shown that not only can optical performance be matched, but also thermal performance!

What about strength? Aren’t you losing a lot of material? In fact, the entire module becomes stronger. Traditional lamination traps manufacturing imperfections between multiple layers, creating stress concentrations that build up across the panel - especially near the delicate solar cells.